Checking Out the Versatile Makes Use Of and Applications of Light Weight Aluminum Castings in Modern Industries

Light weight aluminum spreadings have actually come to be integral to numerous modern-day markets because of their distinct homes. They provide substantial benefits in weight reduction, thermal conductivity, and corrosion resistance. From automotive innovations to applications in customer products and construction, their flexibility is impressive. The true extent of their effect prolongs beyond immediate advantages, hinting at more comprehensive implications for sustainability and effectiveness. What exists ahead for aluminum spreadings in an ever-evolving industrial landscape?

Automotive Market Innovations

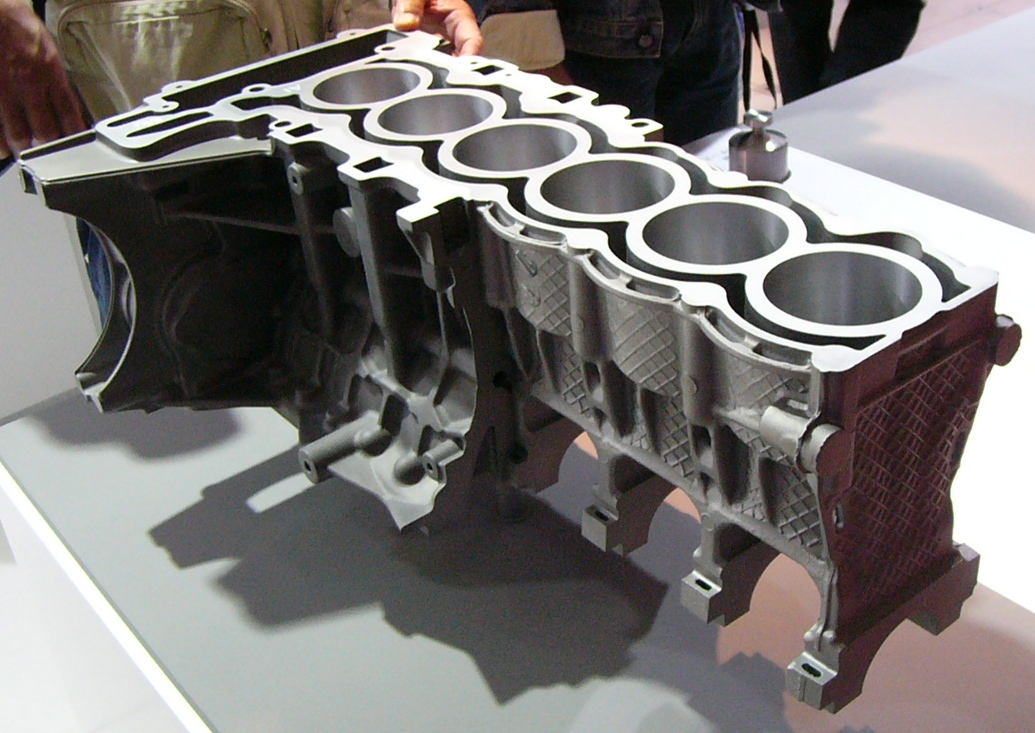

The vehicle industry has actually progressively embraced light weight aluminum castings to improve car performance and effectiveness. By using light weight aluminum, manufacturers can generate lighter elements, which contribute to improved gas economic climate and lowered discharges. Trick applications include engine blocks, transmission cases, and architectural parts, where the material's strength-to-weight ratio delivers sturdiness without adding excess weight.

Light weight aluminum spreadings additionally offer premium thermal conductivity, which assists in better warmth dissipation, consequently improving engine performance. In addition, innovations in casting modern technologies, such as die casting and sand casting, enable the production of complicated geometries, enabling innovative layouts that enhance room and capability.

The recyclability of light weight aluminum straightens with sustainability goals in the automobile sector, promoting eco friendly methods. As the sector remains to innovate, using light weight aluminum spreadings is most likely to increase, driving additional innovations in car layout and efficiency.

Aerospace Applications and Innovations

While the aerospace market proceeds to prioritize weight reduction and fuel efficiency, aluminum castings have become a crucial product selection for different applications. Their lightweight nature, paired with high strength-to-weight proportions, enables substantial improvements in aircraft performance and effectiveness. Light weight aluminum spreadings are typically made use of in architectural components, such as body structures and wing parts, where lowering weight is essential.

Recent advancements in light weight aluminum spreading innovations, including enhanced alloy formulas and accuracy casting strategies, have further boosted the material's performance capabilities. These developments allow the manufacturing of intricate geometries and intricate designs while keeping structural integrity. Furthermore, aluminum's outstanding deterioration resistance warranties longevity and reliability in harsh aerospace settings.

As the aerospace industry progressively embraces sustainability, aluminum castings use a recyclable service that straightens with green techniques, making them an essential aspect in the growth of next-generation aircraft.

Consumer Goods and Everyday Products

As consumers progressively look for lightweight yet resilient materials for daily products, light weight aluminum castings have acquired popularity in different durable goods. The special buildings of aluminum, including its resistance to corrosion and superb thermal conductivity, make it a suitable choice for things like kitchenware, family devices, and outside gear. For instance, aluminum cast pots and frying pans give even heat distribution, improving cooking performance. Additionally, using aluminum in items such as bicycle frames and baggage assures a balance in between toughness and mobility. Makers value aluminum castings for their versatility, as they can be easily built right into complex shapes while maintaining structural stability. Additionally, the ability to reuse light weight aluminum without degrading its homes straightens with expanding consumer preferences for sustainable items. In general, light weight aluminum castings are integral to the production of durable, practical, and visually pleasing customer products, fulfilling the demands of contemporary way of lives.

Building and Architectural Makes Use Of

Light weight aluminum castings have actually become a crucial part in construction and building style, particularly as a result of their strength and lightweight nature. These residential or commercial properties make light weight aluminum a suitable choice for different applications, consisting of architectural elements, exteriors, and ornamental attributes - Aluminum Foundry. Contractors and designers significantly use aluminum castings for home window frames, doors, and roof, enhancing both capability and looks. The product's resistance to rust better extends its life expectancy, decreasing upkeep costs and guaranteeing durability in diverse environmental problems

Furthermore, aluminum can be easily built into intricate designs, enabling innovative building expressions. Its versatility promotes the production of customized items that fulfill particular layout requirements, from ornate railings to complex assistances. As sustainability becomes a top priority, light weight aluminum's recyclability contributes to its appeal in environmentally friendly building and construction practices. Generally, aluminum spreadings are reinventing the building sector by giving lightweight, resilient, and visually attractive services.

Electrical and Electronic Components

Aluminum spreadings play an important function in the production of lightweight electric rooms, which enhance mobility and performance in various applications. In addition, their exceptional thermal conductivity makes them excellent for heat sinks, making sure peak efficiency and longevity of electronic components. Light weight aluminum's conductive residential or commercial properties add to its usage in different electric conductors, emphasizing its value in modern technology.

Light-weight Electrical Units

Lightweight electric units play a vital duty in safeguarding delicate digital elements from ecological variables and physical damages. Built from light weight aluminum spreadings, these enclosures are valued for their strength-to-weight ratio, making them optimal for various applications throughout industries. Their light-weight nature help in decreasing total system weight, which is essential in portable and mobile electronics. In addition, light weight aluminum's rust resistance boosts resilience, prolonging the lifespan of the encased elements. The capability to mold light weight aluminum right into complicated shapes permits customized styles, accommodating specific needs while making certain reliable heat dissipation. Additionally, these enclosures can be quickly integrated into existing systems, providing flexibility and flexibility in modern-day technological settings. Generally, light-weight light weight aluminum enclosures substantially contribute to the performance of electronic gadgets.

Warm Sinks and Conductors

While several products are used in electronic elements, aluminum spreadings attract attention for their efficiency in warmth administration as warm sinks and conductors. Their exceptional thermal conductivity enables effective heat dissipation, which is important in avoiding the overheating of electronic tools. Light weight aluminum's light-weight nature further improves its suitability for applications where weight is a substantial aspect, such as in aerospace and automobile industries. Furthermore, light weight aluminum castings can be conveniently built into complicated forms, supplying design versatility for optimizing thermal efficiency. The deterioration resistance of light weight aluminum also adds to the longevity and reliability of these elements in numerous environments. As innovation breakthroughs and gadgets end up being a lot more compact, the need for reliable warmth monitoring remedies, like light weight aluminum castings, proceeds to grow.

Marine Market Utilization

The marine industry significantly depends on light weight aluminum castings for their phenomenal durability and deterioration resistance. These residential properties make aluminum an ideal option for numerous applications, consisting of boat hulls, engine elements, and marine equipment. The lightweight nature of light weight aluminum spreadings enables improved fuel efficiency and less complicated maneuverability in boat, which is essential for both entertainment and business vessels.

Aluminum spreadings also give considerable expense advantages as a result of their lengthy life expectancy and reduced upkeep requirements, lowering the total operational expenses for view publisher site aquatic drivers. In addition, the adaptability of light weight aluminum enables intricate designs that can satisfy specific performance demands.

Producers in the marine field use advanced casting methods to generate complex forms, ensuring that components satisfy rigorous security and performance criteria. As the need for high-performance aquatic vessels expands, aluminum spreadings are placed as a key product in improving the functionality and long life of aquatic equipment.

Sustainability and Recycling in Light Weight Aluminum Spreading

Light Weight Aluminum Recycling Refine

Recycling light weight aluminum plays a vital role in reducing ecological effect and conserving resources within the spreading industry. The light weight aluminum recycling procedure begins with the collection of scrap light weight aluminum, which can include old components, producing waste, and post-consumer products. This scrap is after that arranged, cleaned, and shredded right into small pieces to assist in melting.

As soon as prepared, the light weight aluminum scrap is melted in a heater at reduced temperatures than primary aluminum production, considerably reducing energy intake. The liquified light weight aluminum is after that cast right into ingots or various other shapes for reuse in various applications - Aluminum Castings. This closed-loop system permits the efficient recovery of aluminum, protecting its properties while minimizing the need for virgin products. The reusing procedure is a critical element of lasting methods in aluminum casting.

Environmental Benefits

While light weight aluminum casting plays a vital duty in various sectors, its ecological benefits are specifically amazing relating to sustainability and source conservation. The light-weight nature of aluminum adds to power efficiency in transportation, lowering fuel intake and emissions. Furthermore, light weight aluminum casting promotes using recycled materials, significantly decreasing the energy needed for manufacturing contrasted to primary aluminum. This recycling process decreases waste and decreases the environmental impact associated with mining and refining basic materials. Light weight aluminum is 100% recyclable without degradation of its homes, advertising a lasting lifecycle. By selecting light weight aluminum spreading, industries can substantially minimize their carbon impact while promoting source effectiveness, making it an essential selection in the search of ecologically friendly manufacturing practices.

Closed-Loop Solutions

Regularly Asked Concerns

What Are the Key Perks of Light Weight Aluminum Castings Over Other Materials?

Aluminum spreadings supply light-weight properties, excellent rust resistance, and high strength-to-weight proportions. They can be conveniently built right into intricate shapes, provide excellent thermal and electric conductivity, and are economical, making them better over lots of alternative products.

Just how Is the Light Weight Aluminum Casting Process Ecologically Pleasant?

The aluminum spreading procedure is ecologically pleasant due to its recyclability, low energy consumption, and reduced waste manufacturing. Its ability to use recycled materials decreases the carbon footprint, advertising sustainability within manufacturing techniques.

What Prevail Obstacles in Light Weight Aluminum Casting Production?

Common difficulties in light weight aluminum casting production consist of keeping dimensional accuracy, managing thermal contraction, preventing problems like porosity and incorporations, ensuring appropriate mold design, and optimizing manufacturing efficiency while reducing material waste and environmental impact.

Exactly How Do Aluminum Castings Compare in Cost With Other Production Techniques?

Light weight aluminum castings typically supply affordable expenses contrasted to various other producing methods, especially for tool to high-volume production. Their reduced initial tooling expenses and reliable product use can cause beneficial business economics over time.

What Future Fads Are Expected in Aluminum Spreading Technology?

Future patterns in aluminum casting technology are anticipated to consist of developments in automation, boosted alloy compositions, enhanced reusing approaches, and the integration of 3D printing, all targeted at enhancing effectiveness, lowering expenses, and minimizing ecological effect.

Current innovations in light weight aluminum casting technologies, including enhanced alloy formulas and precision casting methods, have better improved the material's performance capabilities. Light weight aluminum castings have ended up being an essential element in construction and building design, specifically due to their strength and lightweight nature. The aluminum recycling procedure begins with the collection of scrap aluminum, which can include old components, producing waste, and post-consumer items. When prepared, the light weight aluminum scrap is melted in a furnace at lower temperatures than main aluminum production, considerably decreasing power usage. Additionally, light weight aluminum spreading facilitates the use of recycled materials, substantially lowering the power required for production contrasted to primary aluminum.